.jpg)

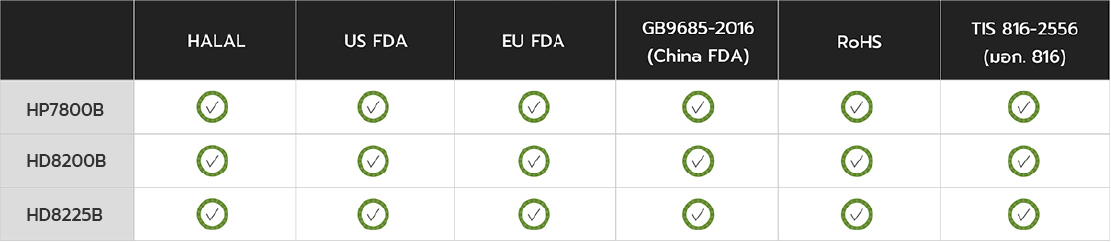

HALAL

Islamic law for food related goods/ product

We manufacture plastic resin for Solar floating pontoon application with various qualifications to support renewable energy concept and environmental friendly.

We aim to contribute to the success of our customers based on strong innovation, concentrating on quality and efficiency, technical service and a global manufacturing platform.

We continue to develop the best quality products to enable business trends and consumer lifestyles to be more functional and sustainable.

Solar Floating Pontoon product segment is mainly focus on solar floating pontoon.

Main float is a primary float for the installation of solar cell.

Secondary float is used to arrange the main float in line and interfacing the float together to create a pathway.

.jpg)

Islamic law for food related goods/ product

.jpg)

Food and Drug Administration (FDA) Specifications according to U.S. FDA 21 Code of Federal Regulations part 177.1520 (c) (2.1)

.jpg)

Plastic materials and articles intended to come into contact with food

““The Hygienic Standards for Uses of Additives in Food Containers and Packaging Materials” under GB31603-2015”

Restriction of Hazardous Substances : EU Directive 2011/65/EU

.jpg)

Polyethylene Industrial Standard

International Standard Compliances by GRADE

Q : Drawdown by its own weight

A :

- Lower processing temperature

- Increase the parison extrusion speed

- Close mold faster

- Use resin with low Melt Flow Index

Q : Improper position of die pin

A : Adjust the position of die pin follow with product

Q : Molding condition or mold design of pinch off area is unsuitable

A :

- Revise design appropriate pinch off section

- Lower the temperature at the pinch off area

- Extend the mold clamping and blowing time

Q : Improper mold design on processing condition

A : - Improve the parting line of the moldQ : Melt fraction occur

A :

- Reduce the extrusion speed

- Raise the die temperature

- Adjust width of die gap

Q : Air release inside mold is unsufficient

A :

- Sandblast the cavity surface as surface treatment of die

- Raise the die temperature

- Raise the pressure of air blowing

Q : Moisture material

A : Check the resin

Q : Too high screw speed

A : Reduce the screw speed

Q : Flight depth of Feeding zone is too deep

A : Check the flight depth of the problematic machine compare with other machine

Q : Foreign material contaminate with resin or degraded resin remain between die and pin

A :

- Clean die

- Check raw material e.g. recycle resin, color master batch