What is Bioplastics?

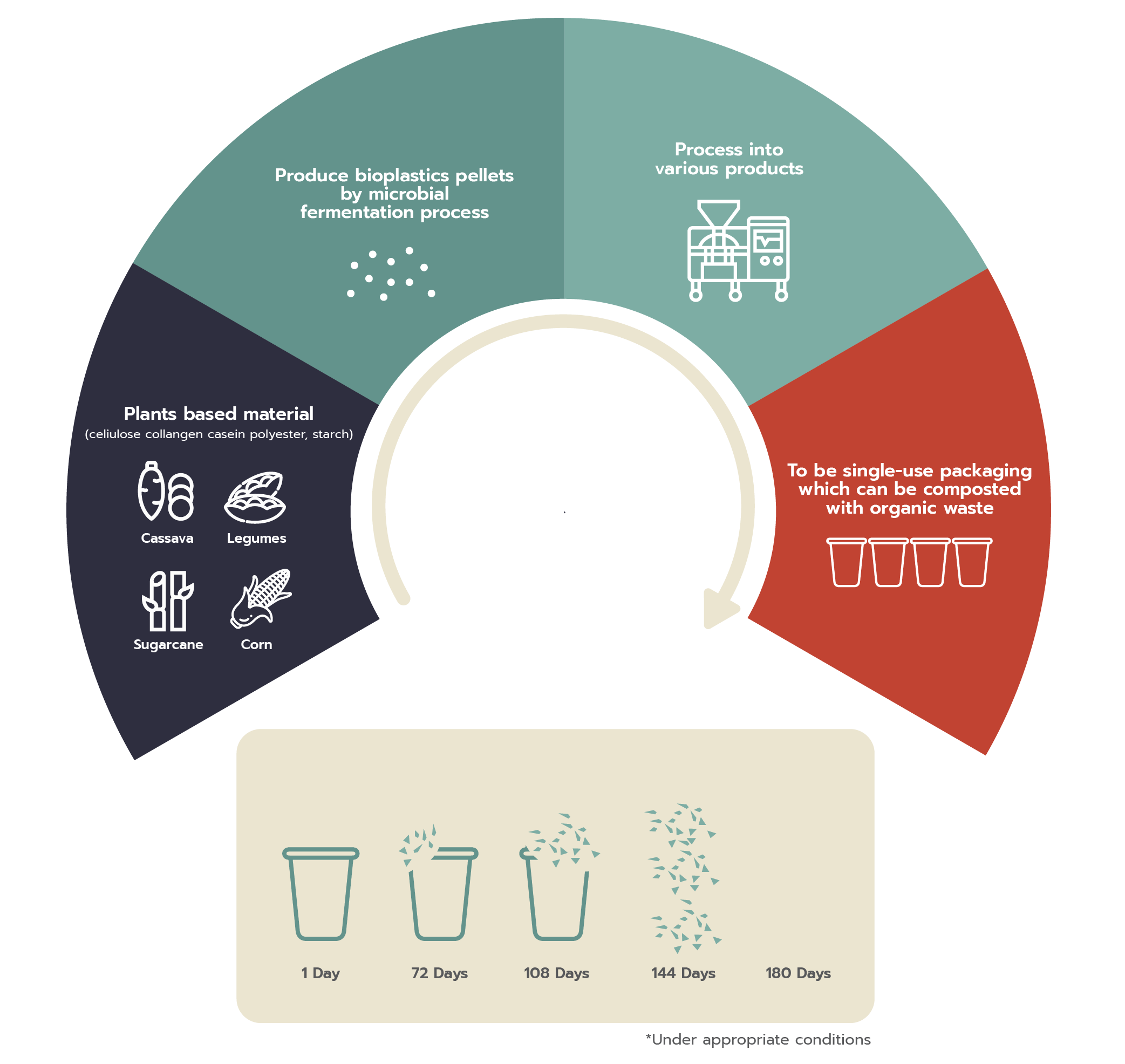

Bioplastics are plastics derived from agricultural raw materials (Biobased) or petroleum (Petrobased). Bioplastics have a plastic-like quality. They can be melted and formed by general processes with general machines; only slight adjustments may be needed. For bioplastics made from agricultural raw materials, they are produced by a fermentation process that converts agricultural raw materials into monomers, which are then used to produce plastic pellets. Currently, the raw materials used in bioplastics production in Thailand are corn, sugarcane, and cassava.

What Are the Types of Bioplastics?</

Type of Bioplastics

Bioplastics include a wide and growing category of biological material based polymers that have their own unique attributes and uses. With new inventions happening in the field, the list is continually expanding. Bioplastics are usually categorized into three main groups:

Biobased but Non-compostable Plastics – These include the bioplastics made out of bio polyesters. Polyethylene (PE), polyethylene terephthalate (PET) and certain polyamides (PA), and polyurethanes (PUR) are included in this category.

Biobased and Compostable Plastics – These include versions like polylactic acid (PLA), polyhydroxyalkanaoates (PHA), polybutylene succinate (PBS).

Petrobased but Compostable Plastics - These include PCL, PBAT, etc.

Benefit of Bioplastics

Sustainable Packaging

Benefit of Bioplastics

Low Non-Renewable Energy

Benefit of Bioplastics

Reduction of Greenhouse Gas (GHG)

Benefit of Bioplastics

Short Life Cycle Assessment - various types can be compostable and suitable for producing single-use products.

Difference between OXO / Biodegradable and Compostable

The Difference between Biodegradable, Compostable, and OXO Biodegradable Plastics

-

Biodegradable plastics

Biodegradable plastics are plastics that degrades in the environment from sunlight, oxygen, humidity and microbes without specific timeline. However there is no accepted standard provided. The compostable standard and its outcome are accepted internationally.

-

Compostable plastics

Compostable plastics are plastics that compost through a biodegradation process into carbon dioxide, water, organic compounds, and humus (soil nutrients) leaving no visible plastic and no toxic residue. The compostable plastic must have a compostable rate comparable to cellulose (ISO 17088) and be certified by international standards. Compostable plastics should be added to a compost pile or buried in soil together with organic waste.

-

OXO-Biodegradable plastics

OXO-biodegradable plastics are plastics that contain pro-degradant additives, such as metal salts, which accelerate their breakdown when exposed to sunlight, UV rays or heat, and remain in the environment. They are also sometimes referred to as Environmentally Degradable Plastic (EDP) instead of OXO-biodegradable.

What is the Bioplastics Standard?

Composability Labels

The Seedling is a reliable label for compostability. The logo and the certificate number printed on the product assists in the purchasing and disposing of a product. The certification process is offered by Belgian certifier TUV Austria Belgium and German certifier DIN CERTCO.

Biobased Label

There is currently no obligation for producers to disclose the exact amount of biobased materials in their products. Producers can, of course, provide this information to consumers on a voluntary basis, and thereby substantiate marketing claims and allow for an informed purchase decision by environmentally conscious consumers.

International Standards for Compostable

The aforementioned organizations specify the criteria for disintegration, biodegradability, and ecotoxicity. Plastics meeting the desired criteria are labeled as compostable.

So how does one identify compostable plastics? Well, all compostable plastics come with a symbol of the certifying international standard. Look for the label on your plastics before purchasing.

The Composition of Compostables

How long does it take compostable plastic to decompose? The tests, under controlled conditions at 55-60°C, are in line with the ASTM D6400, EN 13432 and ISO 17088 standards. The PLA and PBS plastics biodegraded within six months into water, carbon dioxide and biomass, and no residues were left in the environment. However, when testing without standard controls, such as burying PLA and PBS plastics in the soil, or leaving it in a pile of compost, the biodegradation process can take from 6-24 months depending on the temperature and humidity as well as the size and thickness of the material.

What is

Compostable Mark?

Important Requirements in TIS 17088-2555 are as follows:

- Fragmentation during biological fermentation (Disintegration During Composting) determines that the biodegradable plastics were under controlled conditions for 84 days. The residue on the 2.0 mm. force shall not exceed 10% of the total dry solid mass initially.

- Ultimate aerobic biodegradation determines that organic carbon in plastics or additives and fillers, either, must be converted to recovered CO2 in at least 90% of the organic carbon within a period which is not more than 180 days.

- There must be no adverse effects on the ability of compost to support plant growth and comply with regional and/or national regulations, which are:

- Metals and toxins in plastics such as Zn, Cu, Ni, Cd, Pb, Hg, Cr, Mo, Se, As, F must not exceed the specified criteria.

- -Solid, recyclable plastic must not be less than 50% of the total dry solid mass.

- -Plant growth: The requirements of plant growth between plants cultivated with compost obtained from a fragmentation test of plastic fermentation and plants cultivated with compost obtained from a fragmentation test of non-plastic composting are as follows;

- The number of germinated seeds must not be less than 90%

- Mass and dried mass of plants must not be less than 90%

How are Compostables Tested?

What is a BioBased Label?

- Biobased plastics are produced from renewable sources, but may not in all cases biodegrade or be compostable (e.g. Bio-PE, Bio-PET).

- Testing by Radiocarbon or carbon-14 is an isotope analysis according to EN 15440, ASTM D6866, CEN 16137, and ISO 13833 testing method.

.png)

.png)

.png)

International Standards for BioBased

DIN CERTCO

.png)

.png)

.png)

TÜV AUSTRIA

.png)

.png)

.png)

.png)

USDA

.png)

.png)

.png)

Bioplastics Trends

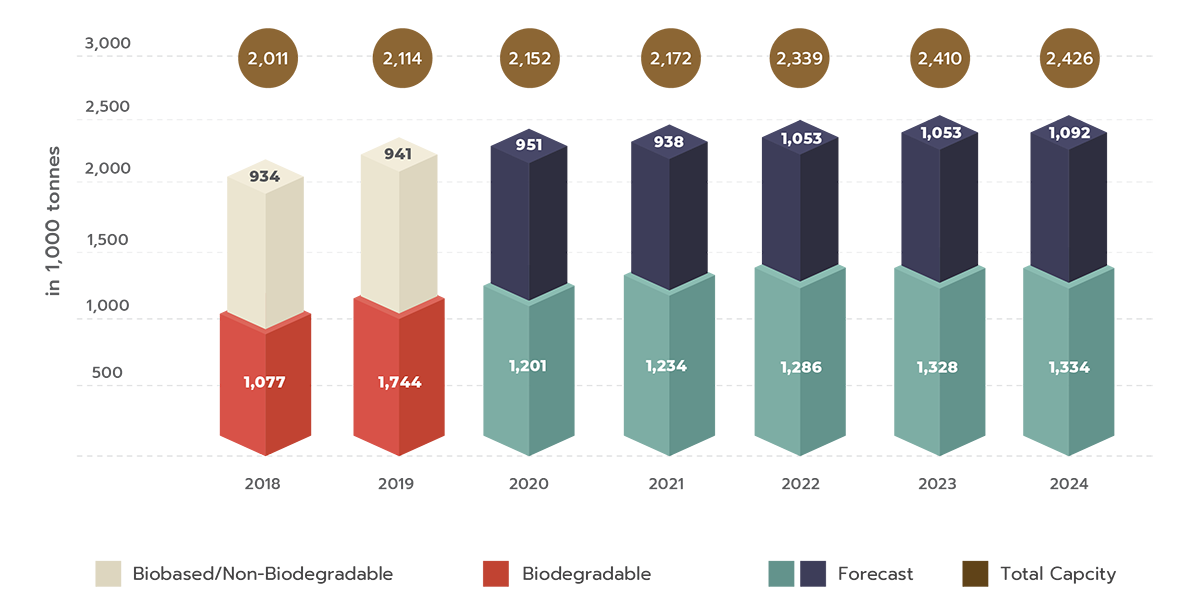

Global production capacities of bioplastics

Global production capacities of bioplastics in 2023 (by region)

Global production capacities of bioplastics in 2019 (by material type)

Global Market Demand

Currently, bioplastic resin represents about one percent of the more than 359 million tons of plastic produced annually. But as demand is rising, the market for bioplastics is continuously growing with strong diversification. Global bioplastics production capacity is set to increase from around 2.11 million tons in 2019 to approximately 2.43 million tons by 2024.

Bioplastics alternatives exist for almost every conventional plastic material and corresponding application. As further bioplastics materials become commercially available, the production capacities will continue to diversify within the next 5 years.

Global Plastics Market

- Bioplastic market is expected to grow at 30% (CAGR 2013-2030)

- Traditional market is expected to grow at 3% annually

.png)

.png)

.png)

Application for Bioplastics

GC Bioplastics Product Portfolio

Introduction of PLA Ingeo by NatureWorks

PLA under trademark Ingeo is produced by Natureworks, a joint venture between

PTT Global Chemical Public Company Limited (GC) and Cargill Company Limited (USA)

https://www.natureworksllc.com/About-NatureWorks

Natureworks is the first world-scale biopolymers producer with 150,000 MTA capacity. The significant features of PLA are:

- 100% renewable source

- Transparent and shiny

- Rigid and brittle (PET, PS like)

- Suitable for rigid fresh food packaging

- 100% compostable in appropriate conditions

- Can be recycled

Sample application of PLA resin:

- Rigid and single-use packaging (thermoforming)

- 3D Printing

- Fiber and non-woven products such as diapers and wet tissue

- Film and packaging

- Bottle (Injection Stretch Blow Molding)

Introduction of BioPBS by PTTMCC

PBS under Trademark BioPBS is produced by PTT MCC Biochem Company Limited (PTTMCC). a joint venture between PTT Global Chemical Public Company Limited (GC) and Mitsubishi Chemical Corporation Company Limited.

http://www.pttmcc.com/new/index.php

BioPBS is produced by PTTMCC, the first and largest BioPBS plant which was commercialized in 2017 at 20,000 MTA capacity.

BioPBS has bio properties. It naturally decomposes into biomass, CO2 and H2O.

Outstanding properties of BioPBS resin:

- 1. Containing renewable carbon

- 2. Fully biodegradable even at ambient temperatures and compostable (EN13432)

- 3. Compatible with end-of life both recycling (repulping operation) and is composting event in backyard

- 4. Has processability similar to polyethylene (PE)

- 5. High service temperature of 100°C

Sample application of BioPBS resin:

- 1. Paper coating

- 2. Mulching films

- 3. Compostable bags

- 4. PLA modifier

- 5. Flexible packaging

- 6. Cutlery

.png)

Paper Coating as Key Applications

Certification & Compliance

BioPBS Cup is Biodegradable in soil within 4 months

Introduction of PlastMate Bio Compound by Solution Creation Company Limited

Bio compound under trademark PlastMate is a product developed by the company’s researchers of PTT Global Chemical Public Company Limited (GC) and distributed by Solution Creation Company Limited, a GC group company.

https://www.pttgcgroup.com/th/markets-innovations/markets/gc-productbrand/plastmate

Bio compound is a bioplastic resin pellet developed by GC researchers using PLA and BioPBS bioplastic products, which are in the GC Group, and further developed to be used in a wide variety of applications such as film, injection, extrusion and punching, and thermoformed parts. Bio compound is also capable of being used in biobased and compostable plastics.

Outstanding properties of PlastMate bio compound resin:

- 1. Containing renewable carbon

- 2. Compliance with Food and Drug Administration (FDA) specifications

- 3. Potentially industrial compostable related to ISO17088 under controlled conditions according to the preliminary study. Fully test and compost certificates are being processed.

- 4. Able to use existing mold and LDPE machine for film and PP/PS machine for Injection application.

- 5. Suitable for food packaging

Application of PlastMate Bio compound:

-

1. Injection

PL34002J: General propose

PL03404J: High heat resistance

- 2. Film

PB05001F: General propose

GC Bioplastics Converter

| Company Name | Product | Brand | Website Link |

|---|---|---|---|

| Thai Nam | Shopping bag | Bio Sure/OEM | Click |

GC Compostable Label

Produced from bioplastics resin and compostable

What is GC Compostable ?

GC is committed to developing products that are environmentally friendly and compostable. The compostability is based on ASTM D6400, EN 13432 or ISO 17088 standards to promote increased awareness among consumers and create a positive brand image for GC’s customers (including convertors and brand owners) that use GC’s bioplastics raw material products with their high standards, to produce bioplastics products. GC created a label certifying that the manufacturers’ products and packaging use compostable bioplastics pellets from GC Group.

This demonstrates a commitment to developing environmentally friendly products, builds confidence, and highlights innovation, which can increase the value of the product or packaging. These labels are for the exclusive use of GC’s end manufacturers to help communicate the benefits of their products and packaging in the market, as well as for other marketing communications purposes. This can support their marketing goals.

Objective

- To support government policies to reduce environmental concerns and global warming problems.

- - To promote customer awareness of products or packaging that use compostable materials or have special qualifications certified by GC Group.

- To promote the image of project participants or product owners in the use of eco-friendly raw material products or packaging.

- To increase opportunities for project participants or product owners to develop products or packaging to meet market needs.

- - To create business partnerships between suppliers, manufacturers and distributors.

GC Compostable Label Standard

This label identifies a product or packaging produced from compostable plastic. A product or packaging with the GC Compostable Label shows that the material is produced and certified by GC Group. GC’s bioplastic resin is certified under the following national and international standards:

- United States standard - ASTM D6400

- European standard - En 13432

- International standard - ISO 17088

Directory of Brands with Registered GC Compostable Labels

| Logo Brand | Product | Company Name | Website Link |

| Cafe Amazon | .png) |

PTT Oil and Retail Business Public Company Limited | Click |

| Cafe Amazon | .png) |

PTT Oil and Retail Business Public Company Limited | Click |

| Cafe Amazon |  |

PTT Oil and Retail Business Public Company Limited | Click |

| Cafe Amazon | .png) |

PTT Oil and Retail Business Public Company Limited | Click |

| Dear Tummy |  |

Intermart (Thailand) Company Limited | Click |

| AIS | .png) |

Advanced Info Services Public Company Limited | Click |

| Leafz | .png) |

Teamplas Chemical Company Limited | Click |

| BIO SURE |  |

Thai Nam Group | Click |

| JT Pack of Foods | .png) |

JT Pack of Foods Company Limited | Click |

| OPURE |  |

Opure Thailand Company Limited | Click |

| Bio-eco | .png) |

Bio-Eco Company Limited | Click |

| kmp | .png) |

K. M. Packaging Company Limited | Click |

| DD Paper Cup |  |

D.D.Papercup Company Limited | Click |

| DD Paper Cup |  |

D.D.Papercup Company Limited | Click |

| Dairy Home | .png) |

Dairy Home Compamy Limited | Click |

| GoodAge | .png) |

Lion (Thailand) Company Limited | Click |

| Doi Kham |  |

Doi Kham Food Products Company Limited | Click |

Project and Campaign

The owner of ‘Uncle Saleng’ page admires GC

GC Compostable: the cup that save the earth has been used in Circular Living Symposium 2019

The aftermath of the success of the Circular Living Symposium 2019 still pervasive because it is not just a big event of the year, which includes the world class speakers, that delivers ideas and practice in thinking strategy to the new generation that ‘How to make effective use of the resources on this planet?’... but GC cares about every detail. This is because all food and drink containers are made from compostable plastic pellet, which guaranteed by GC Compostable Label and because of this, “Prem Pruktayanon”, start up founder and the owner of ‘Uncle Saleng and the Lost Garbage’ page has praised the idea of doing business with environmental care.

Lecturer Koh admires new GC innovation.

Preparation in using cup with GC Compostable Label in running event in 2019

“What are we going to do when waste is overflowing in the earth? Here it is - GC Compostable Label,packaging produced from bioplastic pellets which can be naturally composted after used. Therefore, think before using because the survival of the earth is in your hands.”

Lecturer Koh “Veerapol Sawanpitak”

Former University Lecturer and Well-known Marketing Man

The cup that save the earth in the way of ‘Mission to the Moon’.

“ Solving environmental problems must start from ourselves. Cup with GC Compostable Label is the cup that save the earth which can be naturally composted because it is made from GC bioplastic pellets which is another small way to create the better beautiful world.”

It is a small part that helps to make our world more beautiful.

Biobased Label

.png)

.png)

.png)

Can Be

- Attached to bioplastics products which are compostable to promote value of using bioplastics (upstream to downstream)

- Presented with biobased but non-compostable products to build awareness for bioplastics products

Application

- All products using biobased plastics: our goal is to promote biobased durables and non-compostable packaging and bottles, including durable products and BioPET bottles

Material

- BioPBS, PLA, Bio PET: neat resin and compounding with both other bioplastics and conventional plastics

How to Validate the Biobased Content

No agency has issued a certification mark for Biobased Products. The only agency that provides C-14 measurement testing services is the National Institute of Nuclear Technology (Public Organization) or TINT.