.jpg)

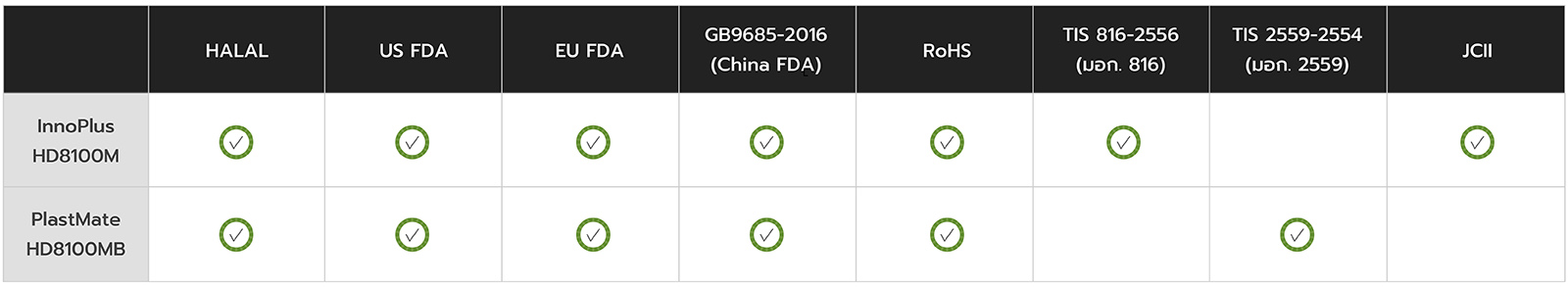

Halal

Islamic Law for Food Related Goods/Product

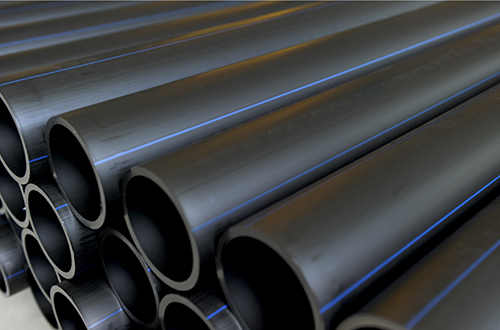

We are committed to producing high quality and innovative HDPE resins for pipe material applications for water supply systems and the construction industry.

We aim to contribute to the success of our customers based on strong innovation, concentrating on quality and efficiency, technical service and a global manufacturing platform.

We continue to develop the best quality products to be more functional and sustainable and to serve business trends and varying consumer lifestyles.

Pipe product segments are divided into 3 main applications: water supply, construction and infrastructure, and industrial and chemical.

• HDPE Water pipe (PE100)

• HDPE Pipe Fittings

• HDPE Water Pipe

• HDPE Pipe Fittings

• HDPE Pipe Fittings

• HDPE Conduit Pipe

• HDPE Pipe Fittings

• HDPE Conduit pipe

• HDPE Corrugated Pipe

• HDPE Pipe Fittings

• HDPE Corrugated Pipe

• HDPE Gas Pipe (PE100)

• HDPE Gas Pipe (PE100)

High density polyethylene pipe with good mechanical properties. It is resistant to weather conditions and flexible.

Has good mechanical properties and is resistant to weather conditions. It’s flexible and easy to install.

Has a non-brittle quality and is lightweight. This makes it easy to install and manage and also minimizes damage during transportation and storage.

To be used with pipes and electric systems. It is resistant to pressure and weather conditions and it’s flexible and meets the compound requirements of ISO4427.

Polyethylene pipe resins create a pipe with high resistance to pressure and weather conditions. It is also flexible and meets the compound requirements of ISO4427.

.jpg)

Islamic Law for Food Related Goods/Product

.jpg)

German Food Articles of Daily Use and Feed Code of September 1, 2005 (LFGB), Section 31 - Sensory Examination Odour and Taste Test

.jpg)

Food and Drug Administration (FDA) Specifications accordingto U.S. FDA 21 Code of Federal Regulations part 177.1520 (c) (2.1)

.jpg)

Plastic Materials and Articles Intended to Come into Contact with Food

.jpg)

Sanitation STD. for Food Utensils, Container and Package.

Japan Chemical Innovation and Inspection Institute

.jpg)

“The Hygienic Standards for Uses of Additives in Food Containers and Packaging Materials” under GB31603-2015

.jpg)

Restriction of Hazardous Substances: EU Directive 2011/65/EU

.jpg)

Polyethylene Industrial Standard

.jpg)

According to ASTM D3421-1975

Q : Improper die setting

A : Adjust the die setting

Q : Improper alignment of die and take-off units

A : Check for alignment

Q : Hot and cold spots in die profile temp

A : Check for uniformity in die heating

Q : Maybe due to moisture in resin

A :

- Pre-dry resin before using

- Reduce screw speed

- Check for leaking in warehouse facilities, handling and transfer systems

Q : Improper mixing of resin and additives

A : Increase rpm back pressure for better mixing or decrease mesh of the screen pack for increasing back pressure

Q : Contamination

A :

- Check the for contamination in the resin and the additives applied to the resin

- Keep resins in clean areas free of moisture and dust

Q : Over heating

A : Check for the functioning of temperature controller.

Q : Melt temperature too low

A :

- Increase die temperatures

- Increase extruder temperatures

Q : Contaminates sticking on the mandrel or sizing sleeves

A : Check for contaminates sticking on mandrel or sizing sleeves

Q : Very high linear extrusion speeds can cause melt fracture at the die

A : Reduce speeds

Q : If a strip of roughness on underside, then it is caused by uneven water cascading

A : Direct another cascade from bottom to upward

Q : Misalignment of sleeve and die

A : Check for alignment

Q : Moisture in resin

A :

- Pre-dry resin before using

- Reduce screw speed

- Check for leaking in warehouse facilities, handling and transfer systems

Q : Die gap too narrow

A : Increase die gap

Q : Sizing devices in adequate or out of shape

A : Check for sizing devices.

Q : Pipe is too warm when it reaches the haul off unit

A : Adequate cooling of pipe before reaching the haul off unit

Q : Moisture in resin

A :

- Pre-dry resin before using

- Reduce screw speed

- Check for leaking in warehouse facilities, handling and transfer systems

Q : Resin degradation

A :

- Decrease the melt temperature of the resin

- Increase the screw speed of the lextruder

- Reduce the back pressure

Q : Dirty die

A : Remove any dirt or contaminated material lodged within the die head

Q : Excessive melt temperatures

A :

- Reduce back pressure by increasing diameter of adapter to die or die clearances

- Reduce melt temperature by reducing compression ratio

- Reduce shear by reducing RPM increasing metering channel depth

Q : Operating die zones too high

A : Check for the temperature in proper range