Advanced Search

Results 1221 - 1240 of 2203

FATTY ALCOHOLS

Natural fatty alcohols are derived from vegetable oils and have a chemical composition featuring an even number of carbon atoms per molecule, whereas synthetic fatty alcohols, derived from petroleum products, may have an odd number of carbon atoms per molecule.

Synthetic fatty alcohols can generally be substituted for natural fatty alcohols in the manufacture of certain downstream products.

A substantial majority of fatty alcohols worldwide are converted into surfactants or “surface active agents” which are the basic materials used in the production of laundry detergent, dishwashing detergent and other household cleaning products.

Apart of surfactants, Fatty alcohols are commonly used in a range of goods, including plasticizers, solvents, flavorings, fragrances, detergents, foam stabilizers, lubricant, cosmetics, plastic intermediates, shampoo, paints and coatings, textile and leather auxiliaries and printing inks. Our fatty alcohols are generally categorized as short chain (C6-10), mid-cut (C12-14) and long chain (C16-18), depending on the number of carbon atoms contained in each molecule

For more information Click Here

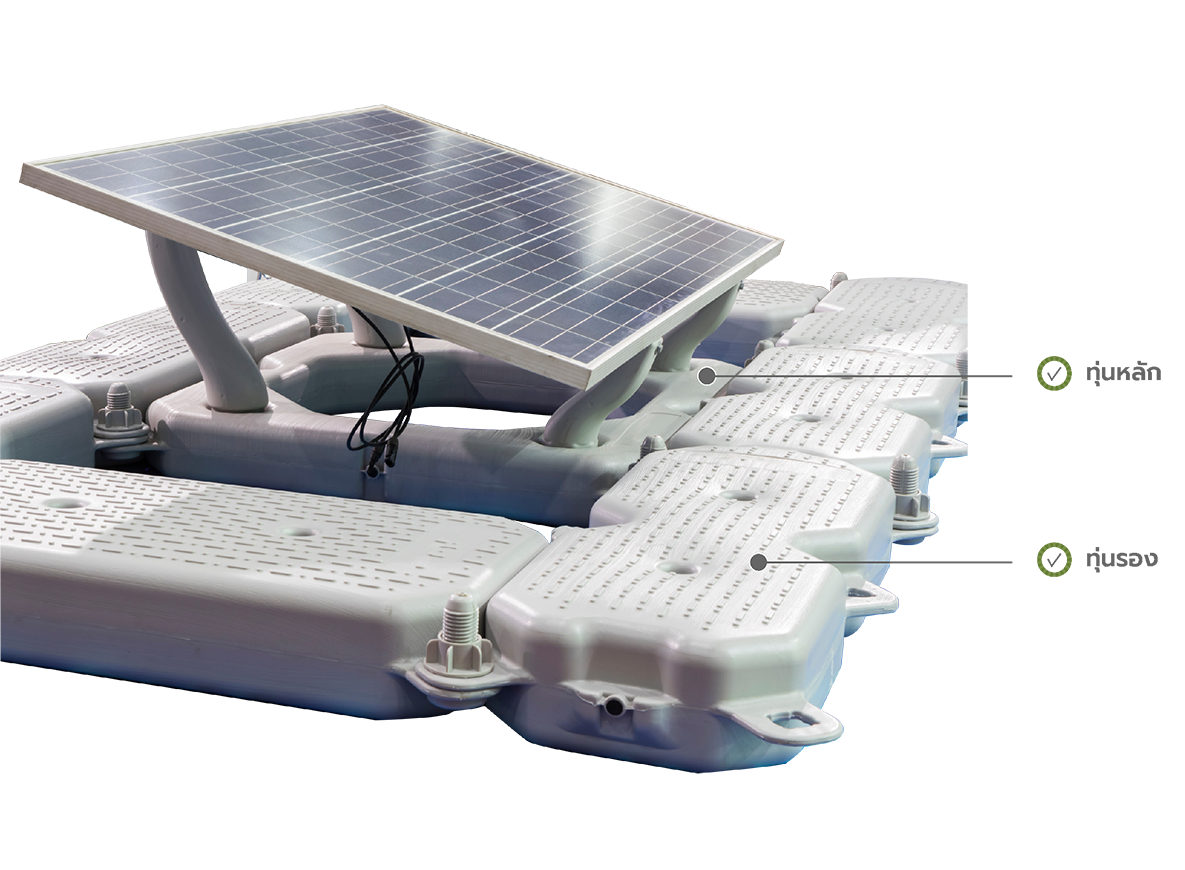

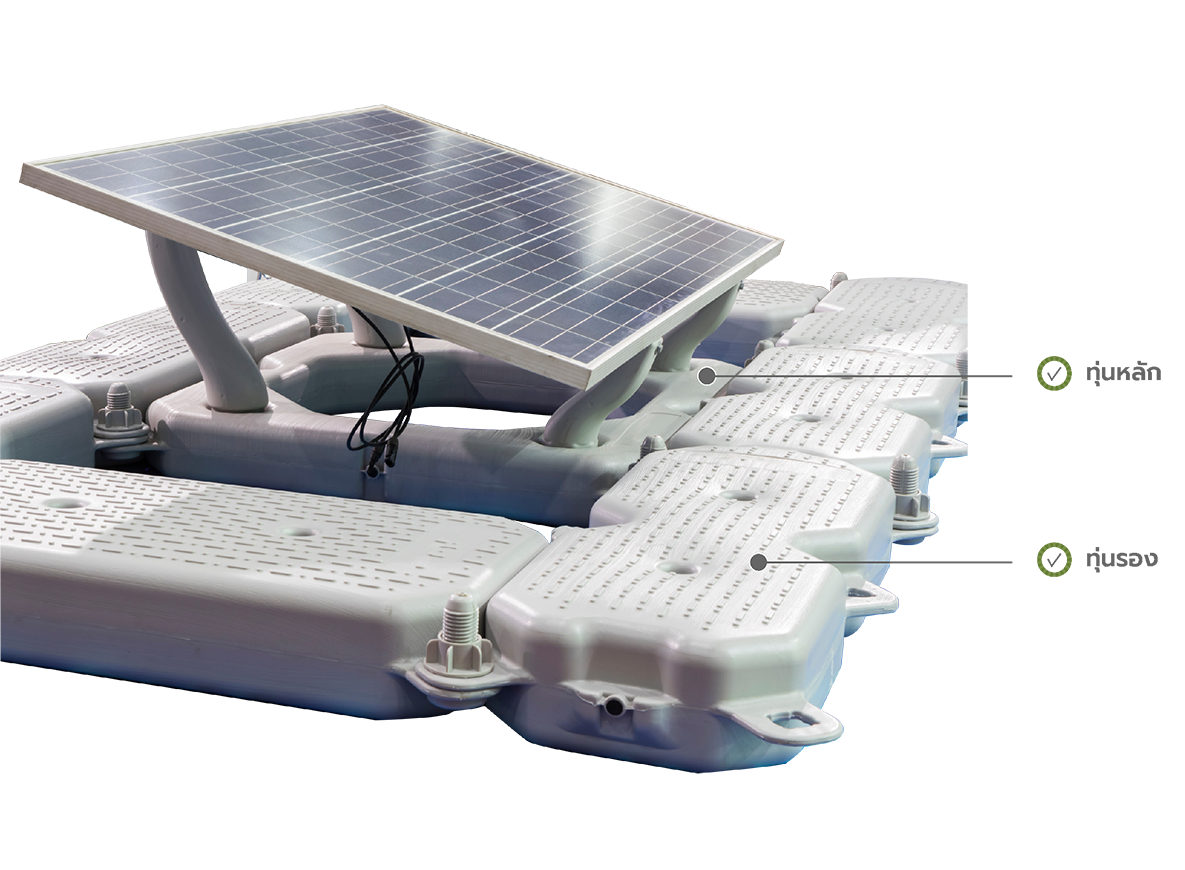

Main Float

Polymer Parts for Solar Floating Pontoon

Main Float

Polymer Parts for Solar Floating Pontoon

Secondary Float

Polymer Parts for Solar Floating Pontoon

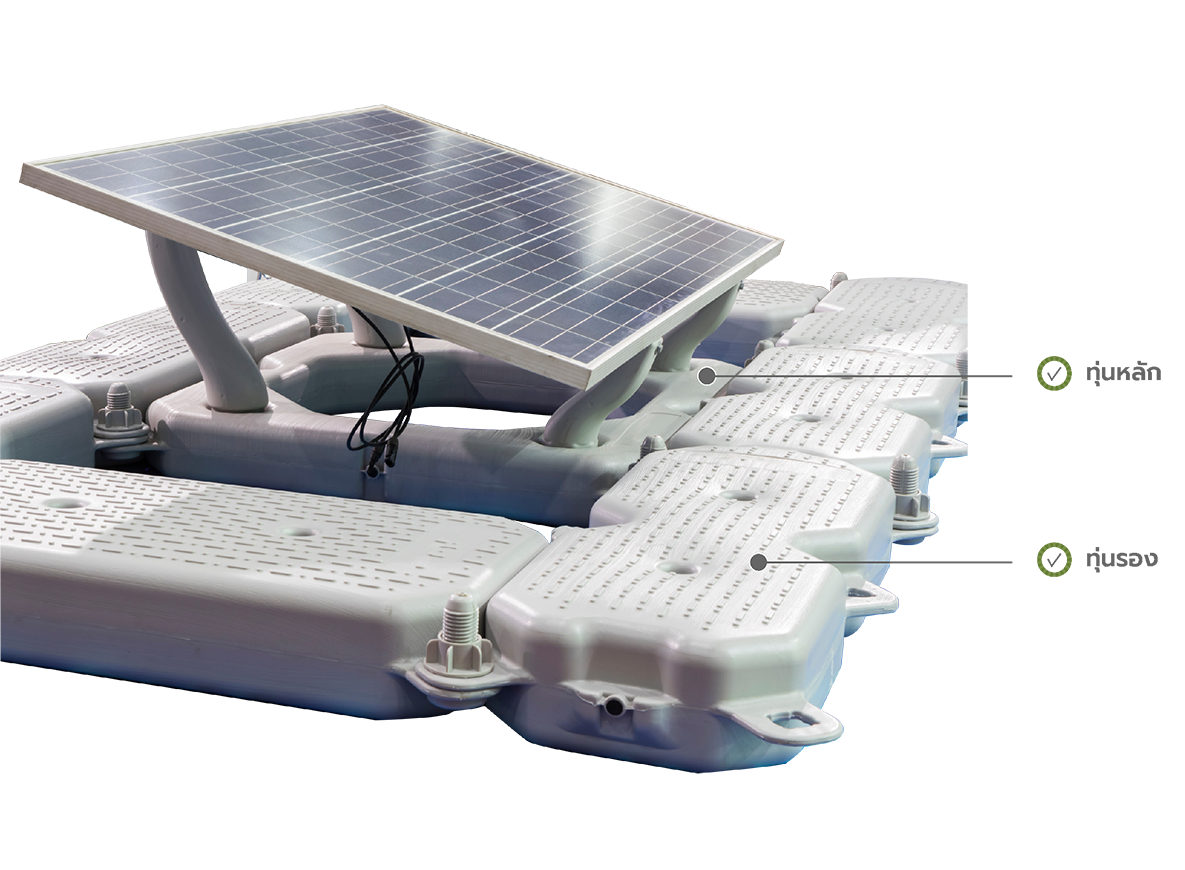

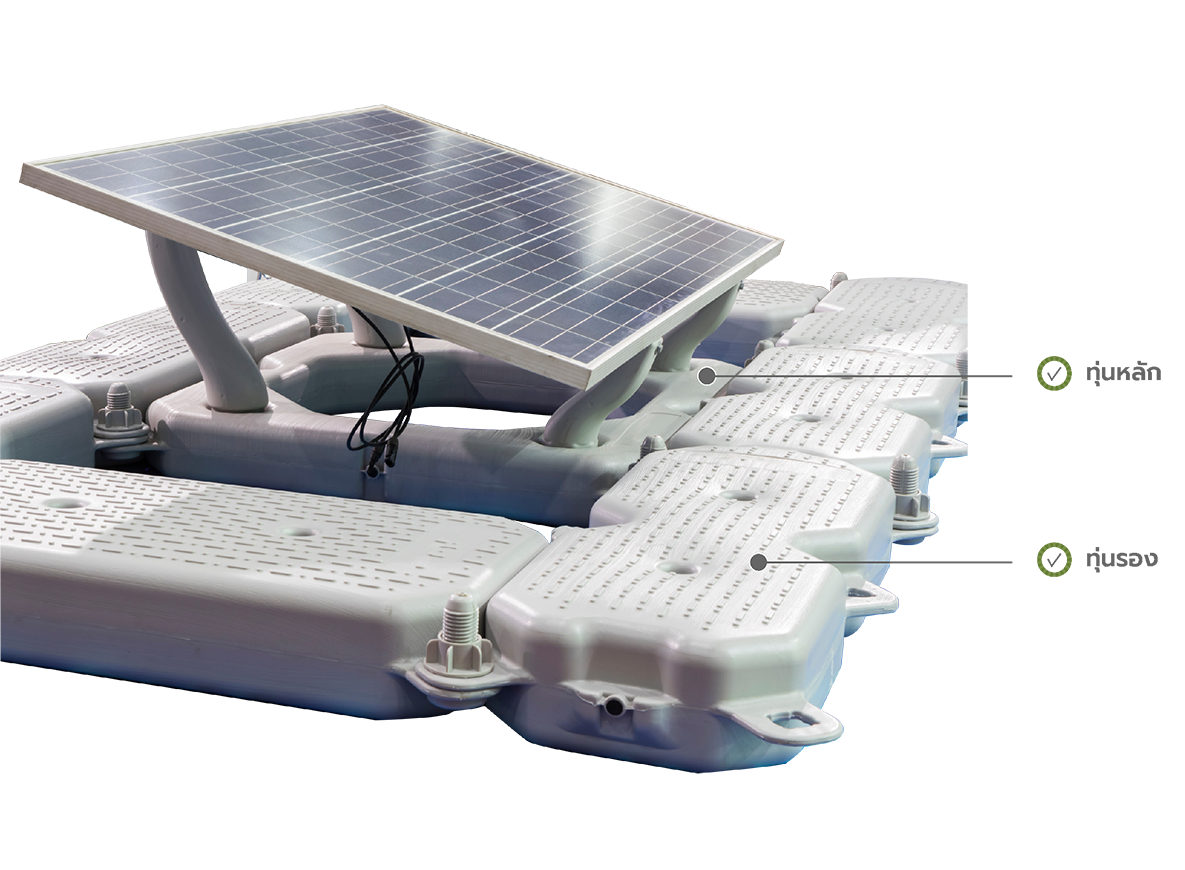

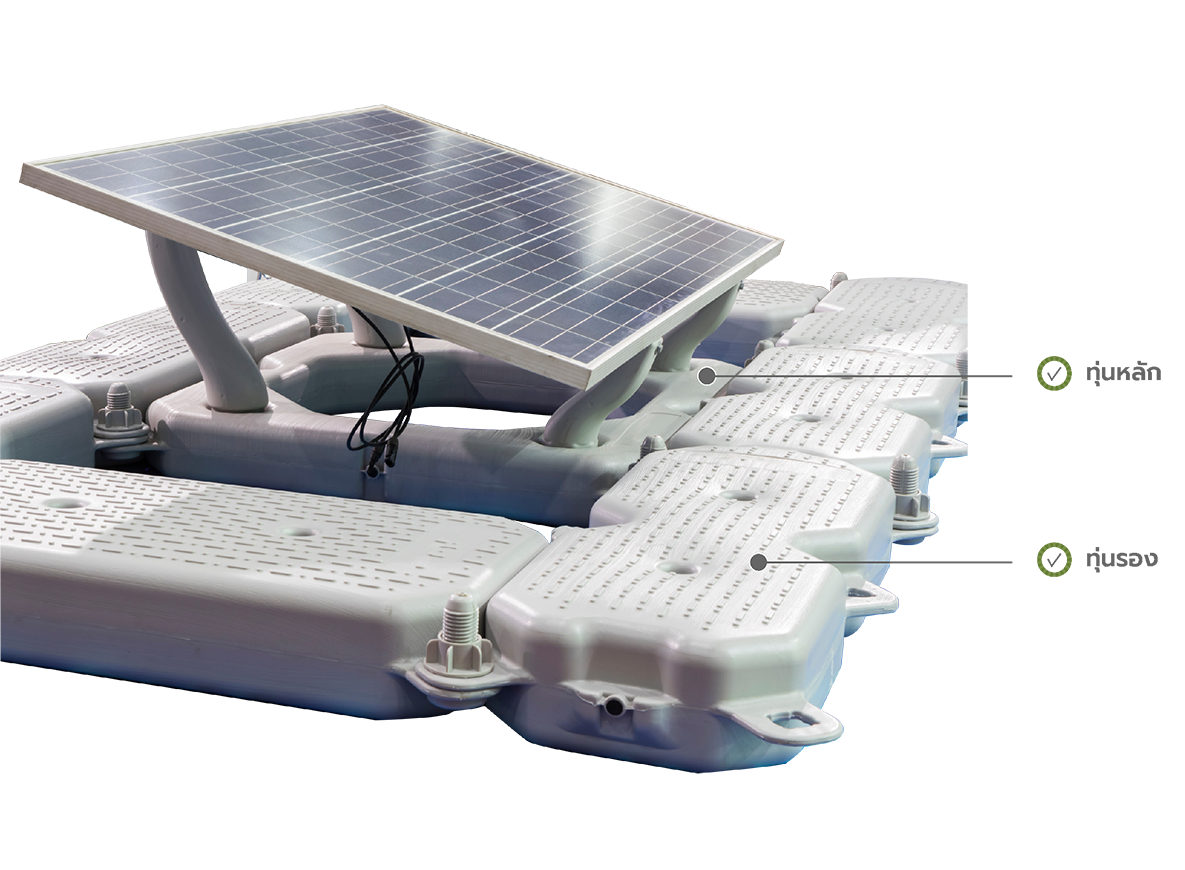

Main Float

Polymer Parts for Solar Floating Pontoon

Secondary Float

Polymer Parts for Solar Floating Pontoon

mPE

Metallocence Low Density Polyethylene (mLLDPE)

InnoPlus by GC Metallocene Polyethylene (mPE) has total production capacity at 300,000 MTA. Produced by low pressure polymerization, using gas phase of Unipol Process under the license of Univation Technology who is leading global technology licernsor of proven metallocence PE technology. These unconventional mPE from variety of catalyst offer a superior puncture and draft impact resistance, good seal ability and excellenct optical property. InnoPlus mPE is widely used for cast and blown film application.

Polyethylene Terephthalate (PET)

Polyethylene Terephthalate (PET)

InnoPlus by GC Polyethylene Terephthalate (PET) has total production capacity at 210,000 MTA. Produced by the leading technological know-how of Lurgi Zimmer GMBH (Germany) and Bühler AG (Switzerland), ensuring consistently supreme product quality in order to complete customer confidence. Both technologies enhance the premium product quality with the high plant operation reliability to serve customer requirement. InnoPlus PET is widely used for bottle and sheet application.

For more information: Thai PET Resin Co., Ltd.

General Film

General Film

General Film Packaging is comprised of LDPE, LLDPE, HDPE which is suitable for general packing products such as chilled & frozen food packaging, dry food packaging zipper bag, bubble film, garbage bag, shopping bag

Heavy Duty Film

Heavy Duty Bags

General purpose film are comprised of LDPE, LLDPE, HDPE and Bioplastics and suitable for general packing products such as Zipper bags, Bubble film, Garbage bags, Shopping bags, Frozen & Chilled bags and Dry food packaging.

Lamination Film

Lamination Film

The multilayer films which produced by lamination process are combined between at least 2 substrates to promote the film functions e.g., mechanical properties, barrier properties and sealability. Lamination film are comprised of LDPE, LLDPE, and HDPE which can be used in printing and sealing layer as well as used in mono material packaging for recyclability which is suitable for food & beverages packaging, personal care and home care packaging.

Lamination Film

Lamination Film

The multilayer films which produced by lamination process are combined between at least 2 substrates to promote the film functions e.g., mechanical properties, barrier properties and sealability. Lamination film are comprised of LDPE, LLDPE, and HDPE which can be used in printing and sealing layer as well as used in mono material packaging for recyclability which is suitable for food & beverages packaging, personal care and home care packaging.

Large Blow Molding Application

Large Blow Molding Application

Large blow molding HDPE grades are typically served for producing large containers for several industrial segments, such as, for food ingredients, chemicals, fulid solvents, and others. The market for HDPE large blow-molded products uses machines that provide high efficiency and good processability. Therefore HDPE large blow-molded products require a balance of easy processing and good mechanical strength to enhance the combination of productivity, cost-effectiveness, strength and stiffness performance. GC’s large blow molding product portfolio offers a comprehensive range of grades to meet a wide variety of high performance requirements.

Caps and Closures

Plastic Resins for Caps and Closures Application

Growth in the beverage and food industry rapidly drives the demand for polyethylene, polypropylene, and resins for beverage caps and closures.

The trend in beverage packaging is to down-gauge with lightweight and standard short neck closures. The use of lightweight closures is spreading through the beverage industry which is aiming to use less polymer but still retain all the performance characteristics of standard caps and closures. The application typically requires a balance of toughness and stiffness, combined with easy processability, and excellent organoleptic properties, particularly for beverage applications which include, still water, pasteurized water and carbonated soft drinks (CSD).

Small Blow Molding Application

Liquid Bottles (Small Blow)

Blow molding is typically used to produce containers or bottles in the liquid bottle segment. The market for HDPE blow-molded products uses machines and materials that deliver faster cycle times and lightweight products. HDPE blow-molded products require a balance of easy processing and good mechanical strength to enhance the combination of productivity, cost-effectiveness, and bottle-strength performance. GC’s blow molding product portfolio offers a comprehensive range of grades to meet a wide variety of performance requirements.

Consumer Goods (Injection & Sheet)

Consumer Goods (Injection & Sheet)

HDPE with excellent formability, flexibility , stiffness, and toughness. High strength and UV resistance. Suitable for injection molding and sheet. It can be used as a basket, storage box, pallet, etc

PCR HDPE (Rigid Packaging)

PCR HDPE (Rigid Packaging)

PCR HDPE is recycled high density polyethylene blow molding grade. They are used for wide variety blow molding applications of small to medium size container, which is collected from 100% domestic waste. PCR HDPE under brand InnoEco by GC are made through a mechanical recycling process that consistently produces high quality PCR resin and scent-free resin. Complying with global standards.

PCR PET Rigid Packaging

PCR PET Rigid Packaging

PCR PET is recycled polyethylene terephthalate which is a post–consumer material. They are used for both bottle and sheet applications. Recycled plastic source is from unpigmented post-consumer recycle PET food and beverage bottle from domestic waste only. PCR PET under brand InnoEco by GC are made through a mechanical recycling process that consistently produces high quality PCR resin. Complying with global standards. 100% high-quality PCR PET with global food safety standard certification

PE Pipe Products

Pipe PE 100

HDPE pipe resins are produced from InnoPlus and PlastMate HDPE resins which are suitable for pressure (e.g. water and industrial pipes) and non-pressure (e.g. conduit and agriculture pipes) pipe applications. The product is non-corrosive and has excellent mechanical properties. It offers high durability and long life service.

Pipes made from HDPE pipe resins are widely used in construction. These products are used to replace metal and cement pipes which convey and transport portable water, gasses, chemicals, industrial fluids, and wastewater. HDPE pipe is lightweight and offers high durability, coilability and easy installation which can save transportation costs and handling costs. It also offers a low maintenance cost after installation. In addition, HDPE pipe compounds are non-corrosive materials which are suitable for water and chemical transportation. The HDPE pipe is available in a wide range of diameters up to 2,000 mm.

PCR Rotational Molding Product

PCR Rotational Molding

Problems with using plastics that are difficult to biodegrade It is a national problem that many organizations have been interested in for a long time. because it affects the overall environment This has caused many organizations to develop new innovative solutions to solve this problem. Currently, there is development to produce PCR plastic pellets as recycled plastic pellets that can meet the needs of saving the world while using plastic with peace of mind. It is both safe and environmentally friendly and can be remanufactured into various packaging or even furniture. It can be done with today's innovation and technology.