Advanced Search

Results 1701 - 1720 of 2205

Gallon Cap

Round closures for bulk container with female thread that can be screwed onto a bottle.

Key Features:

- Superior

- Saving

- Reduce

- Recyclable

คุณสมบัติโดดเด่น ได้แก่

- ทนทาน ไม่แตกร้าวง่าย

- หมุนเปิดง่าย ปิดสะดวก

- ทนทาน แข็ง

- มีน้ำหนักเบา รีไซเคิลได้

What is PCR PET Resin’s Role in Sustainability?

The shift towards sustainability in the plastics industry has increased the demand for recycled materials like PCR PET resin and PCR PET dry blended resin. In this blog post, we’ll discuss what PCR PET resin or rPET is, its applications, its production process, how it promotes sustainability, and why InnoEco by GC resins are the ideal choice for sustainable packaging solutions. This includes innovations like Bottle-to-Bottle recycled systems that close the loop for PET bottle usage.

What is PCR PET Resin?

Post-Consumer Recycled PET resin, or PCR PET or rPET, is commonly sourced from used food packaging and beverages bottles made from PET plastic. By repurposing post-consumer plastic waste, PCR PET or rPET resin helps reduce the demand for virgin plastics and minimizes the environmental impact of plastic production and plastic waste. This recycled material is a sustainable solution for companies with sustainable and environmental goals. It also contributes to reducing overall GHG (Greenhouse Gas) emissions in the plastic lifecycle.

Applications of PCR PET or rPET Resin

PCR PET or rPET resin can be consumed for the production of a wide range of applications, particularly in packaging. Its versatility and durability make it an ideal choice for various products, including recycled beverage bottles for packaging water, juices, and other liquids. Food-contacted grades are suitable for containers that store and protect food items.

Production Process of PCR PET or rPET Resin

The mechanical recycling process of PCR PET or rPET resin involves several stages to ensure the quality and safety of the recycled material:

1. Collection

Post-consumer PET bottles and containers are collected through recycling programs and initiatives. This step is essential for gathering the raw materials needed for recycling.

2. Sorting

The collected plastics are sorted to remove any non-PET materials and contaminants. Advanced sorting technologies ensure that high-quality PET materials are used in the production process.

3. Cleaning

The sorted PET plastics are thoroughly cleaned to remove labels, then grinding and washing to remove adhesives and any remaining impurities. This step ensures that the recycled materials are free from contaminants that could affect the quality of the final product.

4. Processing

The cleaned PET flakes are sorted to remove any non-PET materials and then processed into pellets. This involves melting the plastic and extruding it into the desired shape and removing contaminants in plastics. The material is further refined to ensure quality consistency. Envicco, a leader in high-quality recycled PET production in Thailand, exemplifies this process with advanced mechanical recycling technology.

5. rPET Dry Blended Process

Some resins undergo a specific method known as PCR PET dry blended, which involves blending recycled PET with virgin PET to serve customers who initially require minimum recycled material content for ensuring product properties consistency.

How PCR PET Promotes Sustainability

PCR PET resin plays a significant role in promoting sustainability through several key aspects:

- Circular Economy: PCR PET resin supports the circular economy by recycling post-consumer plastics and converting them into new products. This approach minimizes waste and keeps materials in use longer.

- Waste Reduction: Utilizing PCR PET resin reduces the volume of plastic waste in landfills or oceans. This helps lessen pollution and the harmful effects of plastic waste on ecosystems.

- Conservation of Resources: Using recycled materials reduces the demand for raw petrochemical resources, conserving natural resources required for new plastic production.

- Lower Carbon Footprint: The production of PCR PET resin typically emits fewer greenhouse gases than virgin plastic production, contributing to a reduction in overall carbon emissions.

- Consumer Awareness and Responsibility: Using PCR PET resin in products raises consumers’ awareness of the importance of recycling and sustainability. It encourages responsible consumption and supports a market for recycled products.

Regulatory Compliance: Many regions have environmental regulations encouraging or mandating the use of recycled materials. Using PCR PET resin helps businesses comply with these regulations, which promote sustainable practices. It also aligns with policies like Extended Producer Responsibility (EPR), encouraging producers to take ownership of the entire product lifecycle.

Is PCR PET Resin More Cost-Effective?

The cost-effectiveness of PCR PET resin depends on various factors, including feedstock limitations, market situations, supply chain and logistics, and production processes. The rise in corporate sustainability commitments and strengthened government regulations has significantly boosted demand for recycled content, while growing supply capacity is helping stabilize and enhance PCR’s price competitiveness in the market. Moreover, utilizing recycled plastic, companies can enhance their brand value, which attracts more environmentally conscious consumers and potentially increases sales and customer loyalty. In addition, using PCR PET resin helps companies comply with environmental regulations, avoiding potential fines and penalties that may be incurred for non-compliance.

InnoEco by GC PCR Resins

PTT Global Chemical Public Company Limited or GC offers InnoEco by GC. PCR resins to produce high-quality recycled plastic products. Our InnoEco by GC are known for their exceptional quality and environmental benefits. They’re produced with meticulous quality control to ensure the final product is odorless, free from contamination, and maintains the necessary mechanical properties. Our PCR PET resins are food-contact certified to meet stringent food safety standards of the Thai FDA, making them suitable for packaging food and beverages.

Contact us for more information.

GC participated as a keynote speaker in the RotoMould 25 organized by The Association of Rotational Moulders Australia L

GC, one of the leading plastic resin supplier , participated as a keynote speaker in the RotoMould 25 organized by The Association of Rotational Moulders Australia Ltd. (ARMA) from 19-21 May 2025 in Hobart, Australia.

RotoMould 25 is a global Rotomoulding major event , which compounders, converters and distributors from all over the world attend annually.

Agrichemical Spray Tank

Agrichemical spray tank can be served for both pesticide and insecticide containers.

Key Features:

- Superior

- Strong

- Saving

- Reduce

Outstanding highlights:

- Better Impact Strength

- Superior Processability

- Good Stiffness

- High ESCR

- Reduce Plastic Usage

- Energy Saving

Drums <200 L.

Drum type without handles is classified into 2 types depending on the nature of the lid.

(1) Open head type: this type has an open lid feature with a metal belt which being used for tightening the lid. However the metal belt tightening lid occasionally make not easy to open, but suitable for packing chemicals or food that having high viscosity, such as, core chemical substance of shampoo or Sodium Lauryl Ether Sulfate, etc.

(2) L-ring or Tight head type: this type has 2 small caps with double lids on the top of the container. it is generally suitable for packing chemicals or food with having low viscosity and easy-pouring, such as solvent.

Key Features:

- Superior

- Strong

- Saving

- Reduce

Outstanding highlights:

- Better Impact Strength

- Superior Processability

- Good Stiffness

- High ESCR

- Reduce Plastic Usage

- Energy Saving

Jerry Cans

Jerry Cans product is a rectangular shape container that having a handle for the purposes of easy transportation and pouring the liquid inside the tank. For instances, the liquid substances are chemicals, food, or water. The Jerry Cans has a lid specifically designed for easily pouring the liquid contained in the container.

Key Features:

- Superior

- Strong

- Saving

- Reduce

Outstanding highlights:

- Better Impact Strength

- Superior Processability

- Good Stiffness

- High ESCR

- Reduce Plastic Usage

- Energy Saving

IBC tanks for 820 - 1,250 L

Intermediate bulk container (IBC) also known as IBC tote, IBC tank or pallet tank are reusable purposed cubic-container. Multi-use industrial grade containers are engneered for mass handling, tranport, and storage of either liquids, semi-solids, pastes, or solids.

Key Features:

- Superior

- Strong

Outstanding highlights:

- Excellent storage for liquids, chemicals, or powdered substances

- Good resistance to acids and alkalis

- High density, providing resistance to heat and cold

- Designed for easy transport and space-saving storage

Water Tanks 500 – 2,000 L.

This kind of tanks is a huge plastic bag for containing water or liquid ranging from 500 to 2,000 liters in size. The water tank is normally designed in the cyclendrical shape (circle crosssention) and will be located on the floor where its lid is on the top of the tank.

Key Features:

- Superior

- Strong

Outstanding highlights:

- High Environmental Stress Cracking Resistance (High ESCR)

- High Strength and Resistance

- High Chemical Resistance

- Easy Molding and Adaptability

- Certified to meet food contact safety standards

Drums ≥ 200 L (L-Ring or Tight head)

These types of Drums ≥ 200 L have L-Ring or Tight head lid type and volume-capacity of 200 to 235 liters. Two small lids located at the drum top with narrow mouth are designed suitably for containment of solvent that not too high concentrated (or low viscosity) chemicals or food ingredients in order to allow thier pouring easily.

Key Features:

- Superior

- Strong

Outstanding highlights:

- High Environmental Stress Cracking Resistance (High ESCR)

- High Strength and Resistance

- High Chemical Resistance

- Easy Molding and Adaptability

Drums ≥ 200 L (Open head)

These types of Drums ≥ 200 L have open head lid type and volume-capacity of 200 to 235 liters. With the open lid type, the lid of the drum has a metal belt to tighten its lid to protect the substance coming out from the drum. The drum is engineered suitably for containment of high concentrated chemical substances or food ingredients that having high viscosity, such as, core chemical substance of shampoo or Sodium Lauryl Ether Sulfate.

Key Features:

- Superior

- Strong

Outstanding highlights:

- High Environmental Stress Cracking Resistance (High ESCR)

- High Strength and Resistance

- High Chemical Resistance

- Easy Molding and Adaptability

- Certified to meet food contact safety standards

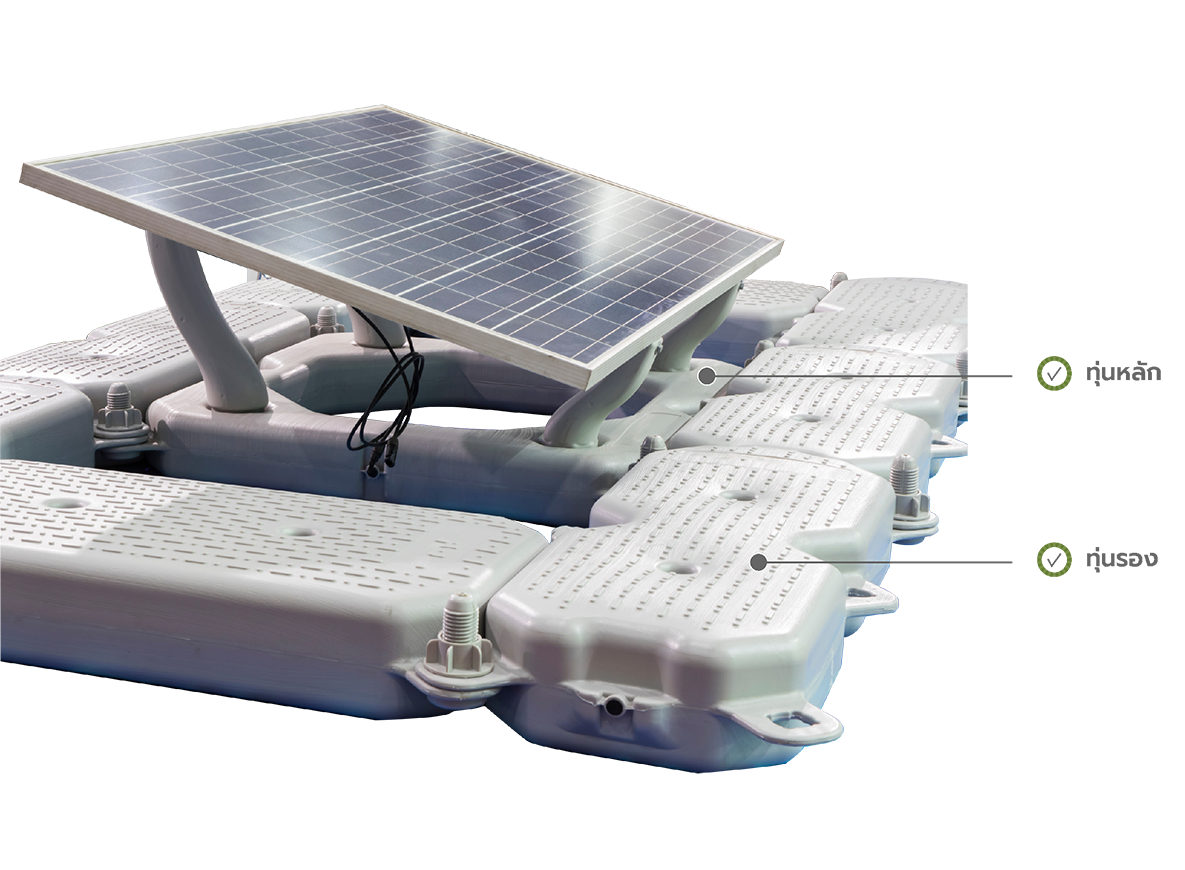

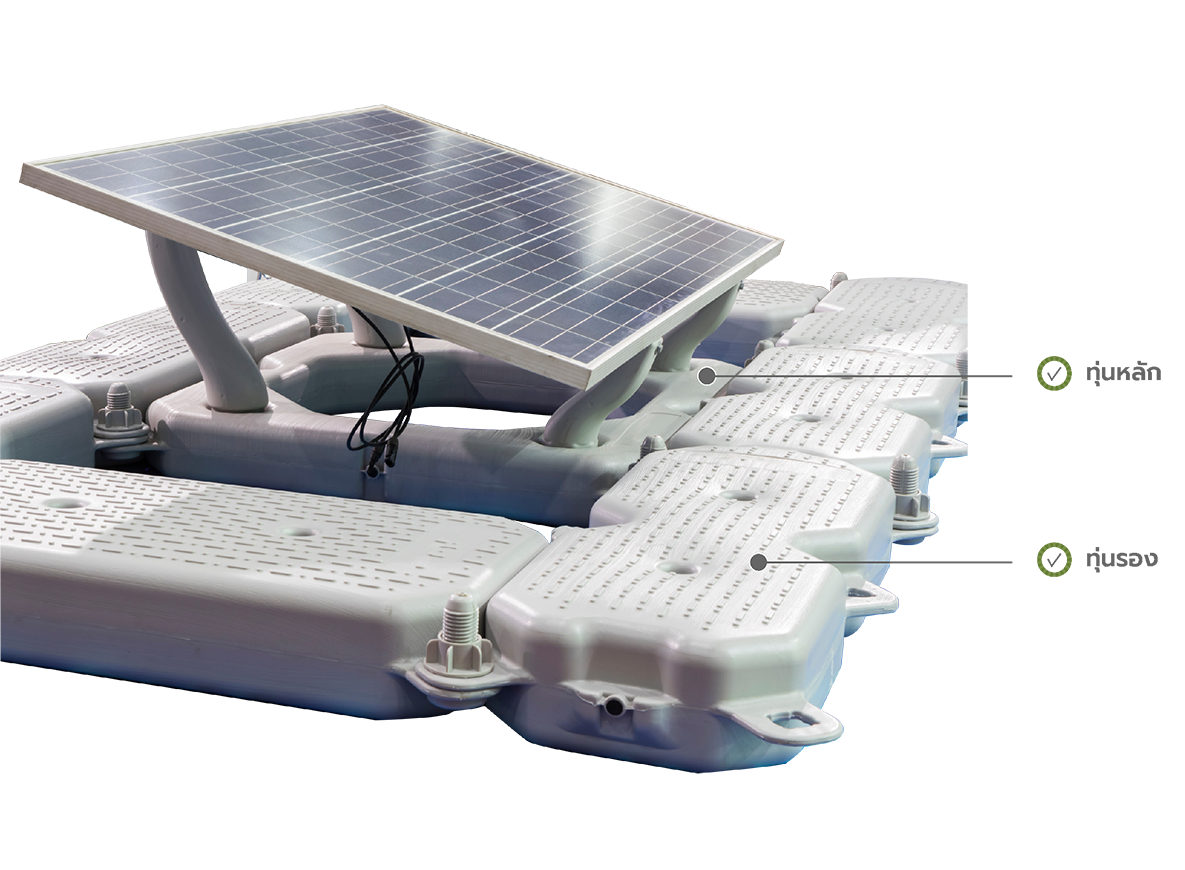

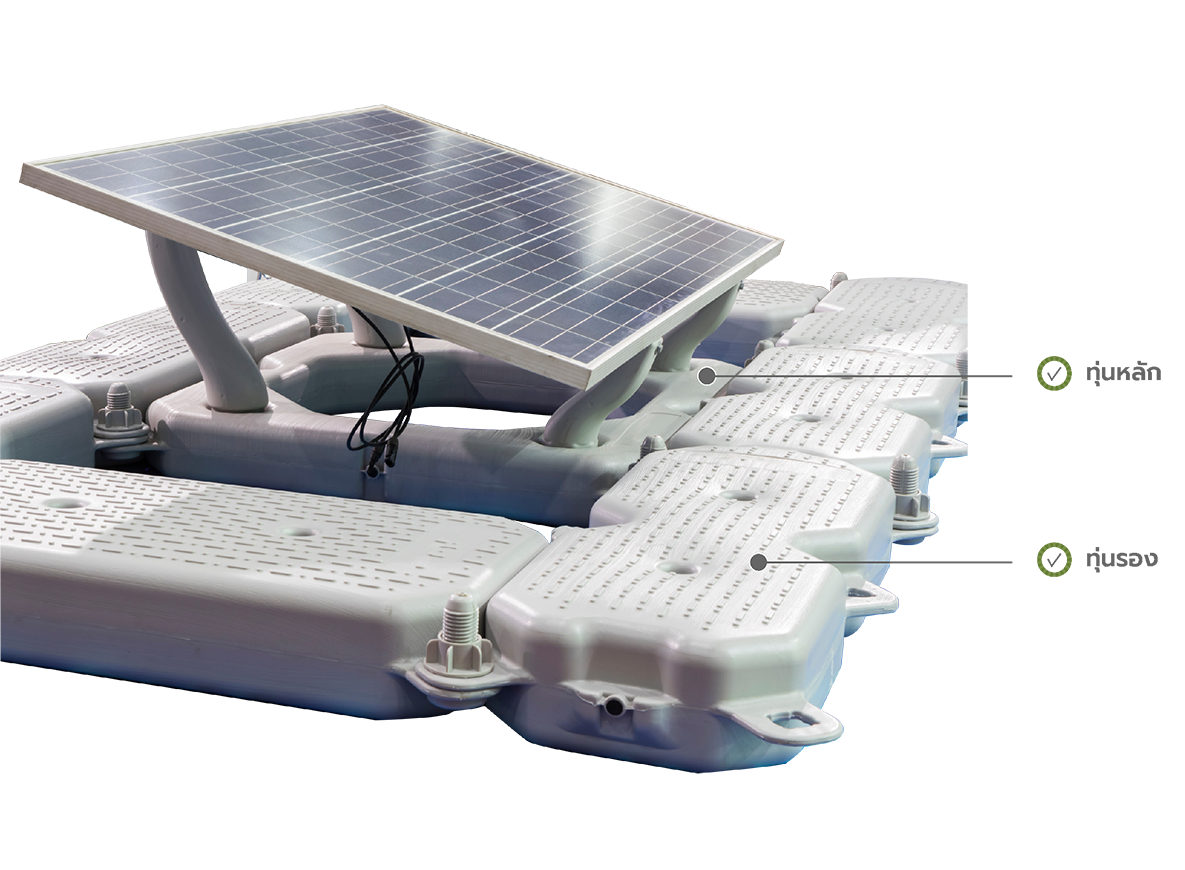

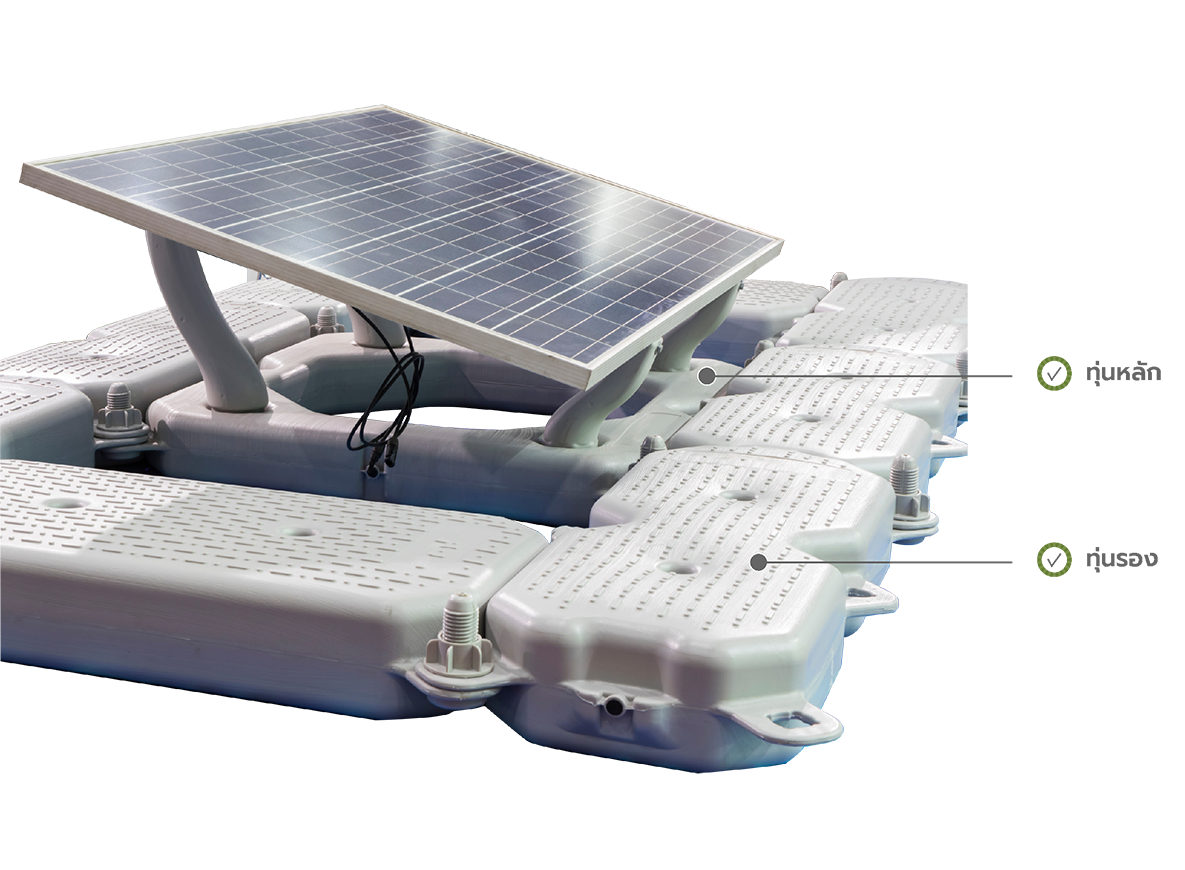

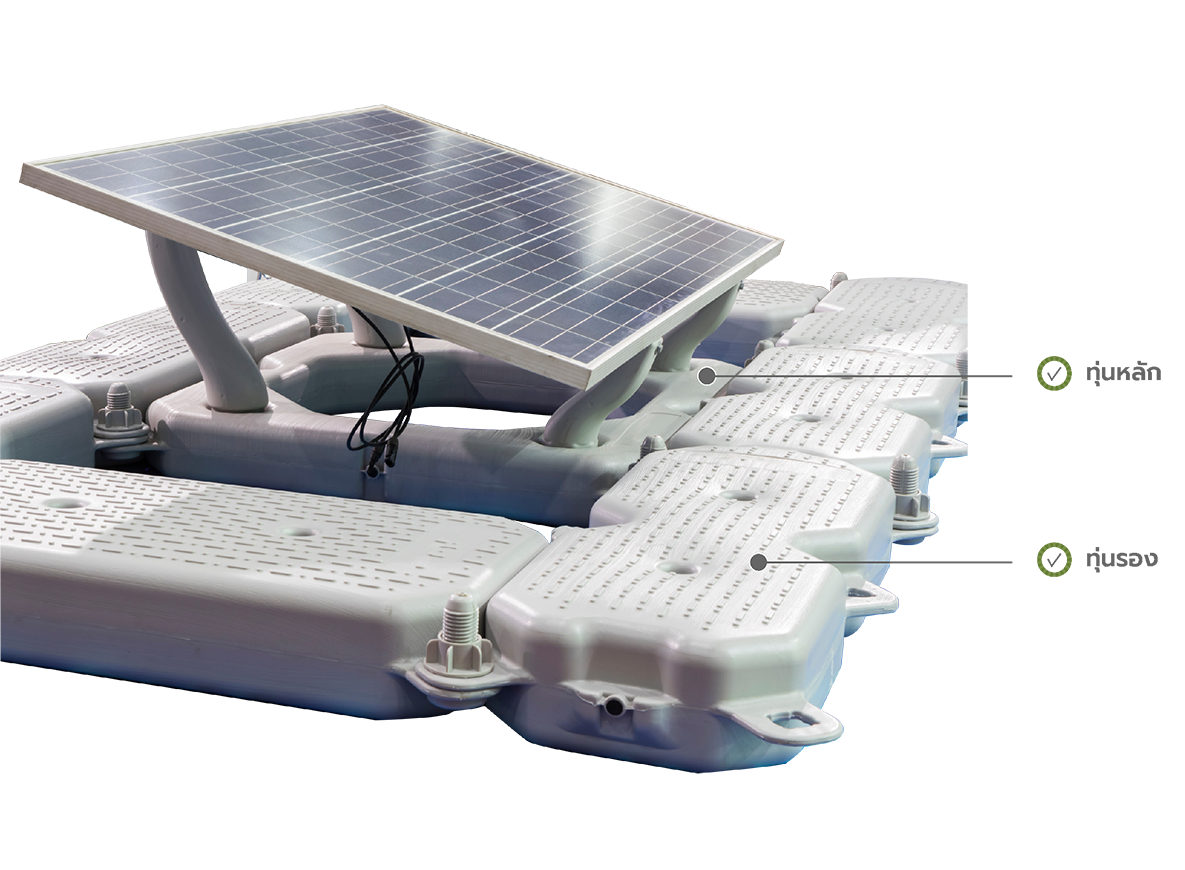

Floating Solar Pontoon

Installations of floating solar panel are popular in many countries where high population density and limited space are concerned. The plastic pontoons are designificated to have enough buoyancy to support the weight of the solar panels and other equipment.

HDPE blow-molding grade are widely used as raw materials for floating solar pontoon structure and specifically formulating designed to be able to offer the resistance to ultra violet radiation and corrosion. Nowadays, the HDPE floating structure has established itself as the most common solution by several suppliers in the market and installed capacity worldwide of solar floating plants.

Key Features:

- Superior

- Strong

Outstanding highlights:

- Better Impact Strength

- Superior Processability

- High ESCR

- Good flexural modulus

- Environmentally friendly.

Main Float

Main float is a primary float for installation of solar cell panal.

Polymer Parts for Solar Floating Pontoon

Key Features:

- Superior

- Strong

Outstanding highlights:

- Better Impact Strength

- Superior Processability

- High ESCR

- Good flexural modulus

- Environmentally friendly.

Secondary Float

Secondary float is used for arranging the main float in the line and interfacing the floats together to create pathway.

Polymer Parts for Solar Floating Pontoon

Key Features:

- Superior

- Strong

Outstanding highlights:

- Better Impact Strength

- Superior Processability

- High ESCR

- Good flexural modulus

- Environmentally friendly.

Secondary Float

Secondary float is used for arranging the main float in the line and interfacing the floats together to create pathway.

Polymer Parts for Solar Floating Pontoon

Key Features:

- Superior

- Strong

Outstanding highlights:

- Better Impact Strength

- Superior Processability

- High ESCR

- Good flexural modulus

- Environmentally friendly.

Main Float

Main float is a primary float for installation of solar cell panal.

Polymer Parts for Solar Floating Pontoon

Key Features:

- Superior

- Strong

Outstanding highlights:

- Better Impact Strength

- Superior Processability

- High ESCR

- Good flexural modulus

- Environmentally friendly.

Main Float

Main float is a primary float for installation of solar cell panal.

Polymer Parts for Solar Floating Pontoon

Key Features:

- Superior

- Strong

Outstanding highlights:

- Better Impact Strength

- Superior Processability

- High ESCR

- Good flexural modulus

- Environmentally friendly.

PCR HDPE for Lubricant, Home and Personal Care Packaging

These high-quality recycled plastic resins are made from 100% domestically sourced post-consumer plastic. They are ideal for manufacturing packaging for engine lubricants, household chemical products, and personal care items. Produced using advanced recycling technology that meets European standards, they ensure excellent performance and reliability.

Key Features:

- Superior

- Recycled

คุณสมบัติโดดเด่น ได้แก่

- ผลิตจากพลาสติกใช้แล้วในประเทศ 100%

- ด้วยเทคโนโลยีการรีไซเคิลที่ทันสมัยมาตรฐานยุโรปตลอดสายการผลิต

- ใช้เทคโนโลยีขั้นสูงในการกำจัดกลิ่น มีมาตรฐานการตรวจสอบและควบคุมคุณภาพ

- นำไปขึ้นรูปได้ง่าย

- รักษ์โลก และลดการปล่อยก๊าซเรือนกระจกในกระบวนการผลิต

PCR HDPE for Lubricant, Home and Personal Care Packaging

These high-quality recycled plastic resins are made from 100% domestically sourced post-consumer plastic. They are ideal for manufacturing packaging for engine lubricants, household chemical products, and personal care items. Produced using advanced recycling technology that meets European standards, they ensure excellent performance and reliability.

Key Features:

- Superior

- Recycled

คุณสมบัติโดดเด่น ได้แก่

- ผลิตจากพลาสติกใช้แล้วในประเทศ 100%

- ด้วยเทคโนโลยีการรีไซเคิลที่ทันสมัยมาตรฐานยุโรปตลอดสายการผลิต

- ใช้เทคโนโลยีขั้นสูงในการกำจัดกลิ่น มีมาตรฐานการตรวจสอบและควบคุมคุณภาพ

- นำไปขึ้นรูปได้ง่าย

- รักษ์โลก และลดการปล่อยก๊าซเรือนกระจกในกระบวนการผลิต

PCR HDPE for Lubricant, Home and Personal Care Packaging

These high-quality recycled plastic resins are made from 100% domestically sourced post-consumer plastic. They are ideal for manufacturing packaging for engine lubricants, household chemical products, and personal care items. Produced using advanced recycling technology that meets European standards, they ensure excellent performance and reliability.

Key Features:

- Superior

- Recycled

คุณสมบัติโดดเด่น ได้แก่

- ผลิตจากพลาสติกใช้แล้วในประเทศ 100%

- ด้วยเทคโนโลยีการรีไซเคิลที่ทันสมัยมาตรฐานยุโรปตลอดสายการผลิต

- ใช้เทคโนโลยีขั้นสูงในการกำจัดกลิ่น มีมาตรฐานการตรวจสอบและควบคุมคุณภาพ

- นำไปขึ้นรูปได้ง่าย

- รักษ์โลก และลดการปล่อยก๊าซเรือนกระจกในกระบวนการผลิต

PCR PET for Foods & Beverage Bottles

Made from high-quality Post-Consumer Recycled (PCR) plastic resins by ENVICCO, InnoEco by GC. PCR PET is ideal for producing food and beverage packaging, perfectly suited for environmentally conscious customers.

ENVICCO is world-class, fully integrated recycled plastic pellet manufacturing facility. It offers innovative dry blended rPET formulations that can be customized to meet the specific needs of different industries effectively (Customizable Solutions). This is achieved under concrete circular economy concept

Key Features:

- Superior

- Recyclable

- Recycled

- Reduced

Outstanding highlights:

- 100% PCR Content

- High Quality with European Standard technology

- Reduce carbon emissions